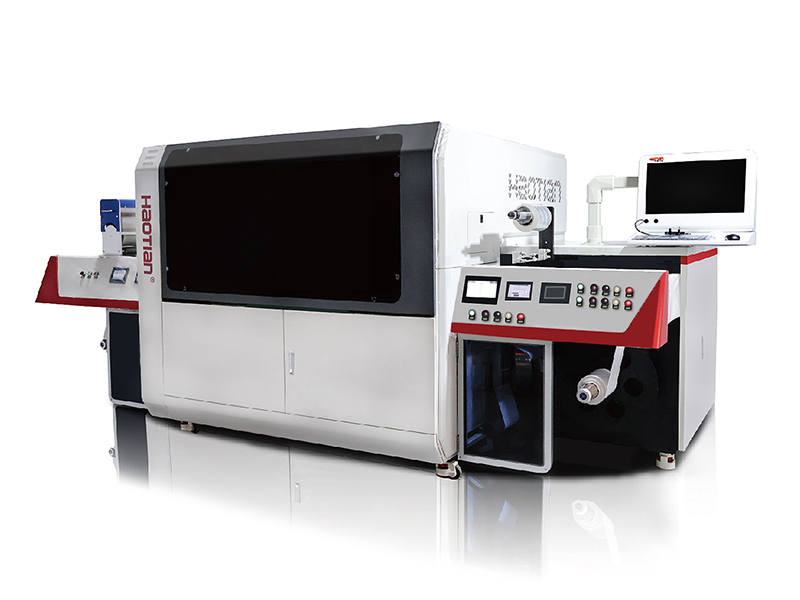

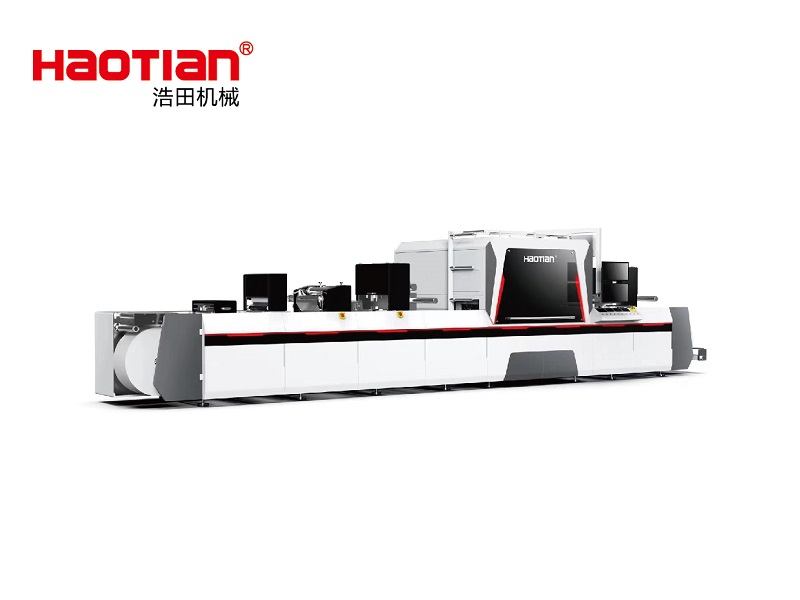

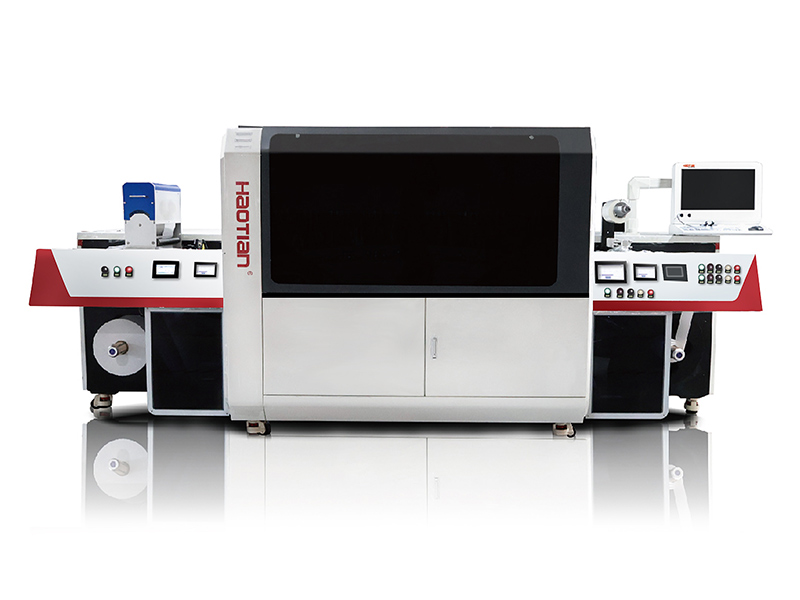

The UV Inkjet Label Digital Printing Machine (HTS-220-7C) expands standard CMYK with white, orange, and violet inks to deliver a broader, more vivid color gamut. Built with a single-pass UV inkjet system and powerful LED-UV curing, it achieves rapid print speeds up to 50 m/min while minimizing material distortion. Its intelligent features—such as automatic nozzle cleaning, a modular ink circulation system, and dual-servo tension control—optimize feed stability, reduce downtime, and enhance operational reliability.

Features

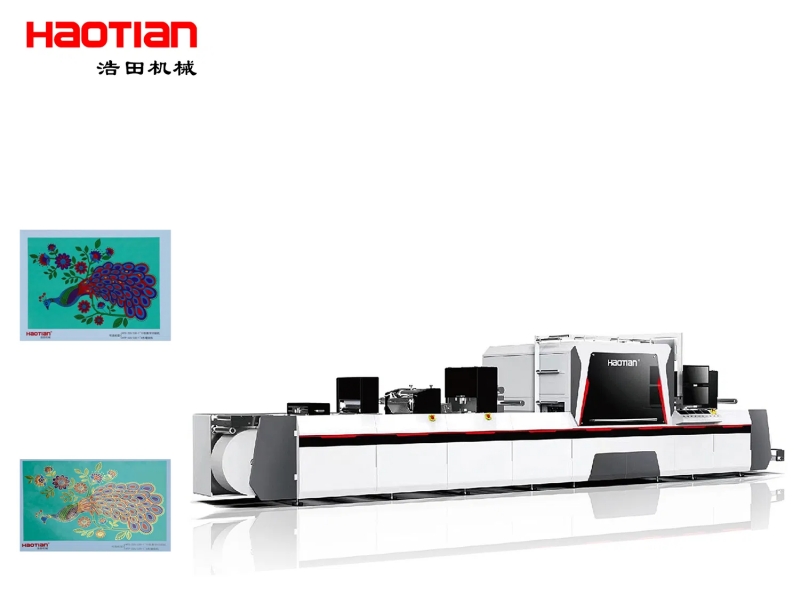

1.The CMYK+W+O+V color group, with a self-developed 7-color separation system, offers a wider printing color gamut, more vivid colors, and more delicate color saturation, further expanding the printing adaptability range. At the same time, it significantly reduces the ink cost in terms of printing consumables, easily achieving full-color printing on both transparent and non-transparent materials.

2.The patented technology of the fully automatic nozzle cleaning and maintenance system (e-clean) effectively cleans and maintains the nozzle module, reduces ink waste during nozzle maintenance and damage to the nozzle caused by human factors, and extends the service life of the nozzle.

3.A mature and stable circulating ink supply system, modular independent positive and negative pressure control, segmented filtration technology, and world-class ink degassing technology ensure the stability and reliability of ink supply.

4.The printing section adopts dual servo tension control, with front and rear material feeding and discharging tension control. The stable and reliable tension control system ensures smooth paper feeding and guarantees registration accuracy.

5.Built-in corona, dust removal and static electricity elimination devices effectively enhance the affinity and adhesion between materials and ink. Reduce the influence of materials and external factors on inkjet imaging and improve printing quality.

Specification

| Printing Technology |

Single-Pass UV Inkjet Techonology With Kyocera Printhead |

Air Source |

0.6 ~ 0.8 MP |

| Resolution |

Kyocera: 600*600 & 600*1200 DPI |

Power Supply |

3 Phase+N+PE/380VAC 50/60 HZ |

|

Printing Speed(m/min)

|

5-50 m/min

The maximum printing speed may vary by complexity of printing file

|

Supported File Formats |

PDF,TIFF |

| Material Type |

Coated or Uncoated Paper, Transparent

or Non-Transparent Materials

|

Computer Hardware |

Mainboard: HTS-Prime Z370-A.

Graphics card: GTX1070-O8G

|

| Winder Roll Diameter |

Maximum 600 mm |

Printing Substrate Thickness |

0.045 -0.8mm For Roll to Roll material |

| Web Width |

Minimum: 220 mm

Maximum: 330 mm

|

Image Processor |

RIP Budling: Synchronizes printing and

RIP for large data files, saving work time.

|

| Actual Printing Width |

Minimum: 216 mm

Maximum: 324 mm

|

Drying Method |

Two-step curing process, each set of

printheads undergoes pre-curing

followed by overall UV curing.

Printhead LED:700W/Lamp

Final UV Curing: 10kwUV

|

| Ink Type |

UV/LED Curing Ink |

| Printing Color Group |

4 -7 colors customized

CMYK+W+O+V

|

Temperature Range |

18 ~ 30°C |

|

Mechanical dimension

(L*W*H)

|

About 4000*2040*1850 mm

Size may vary by customer's required configuration

|

Ink Storage Temperature |

16 ~ 32°C |

| Machine Weight |

About 3500 KG

Weight may vary by customer's required configuration

|

Humidity Range |

40 ~ 60°C |

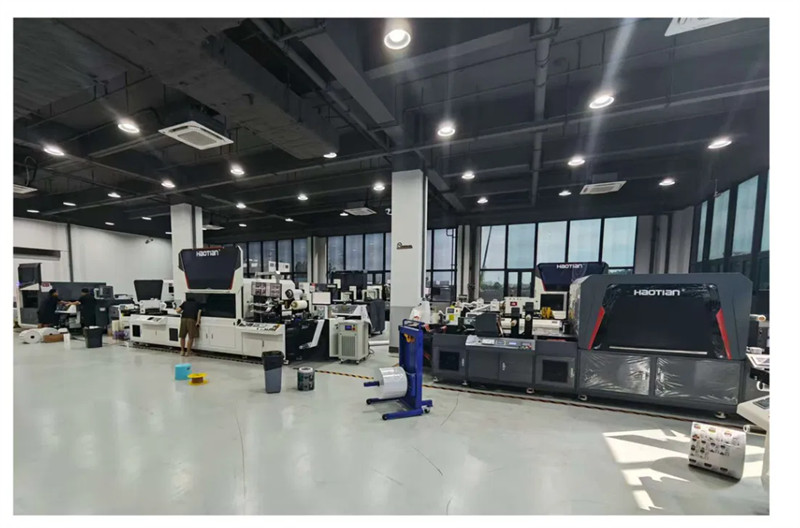

Factory & Packaging

Our Certificate

en

en

Tel :

Tel :  E-mail :

E-mail :

Network Supported

Network Supported