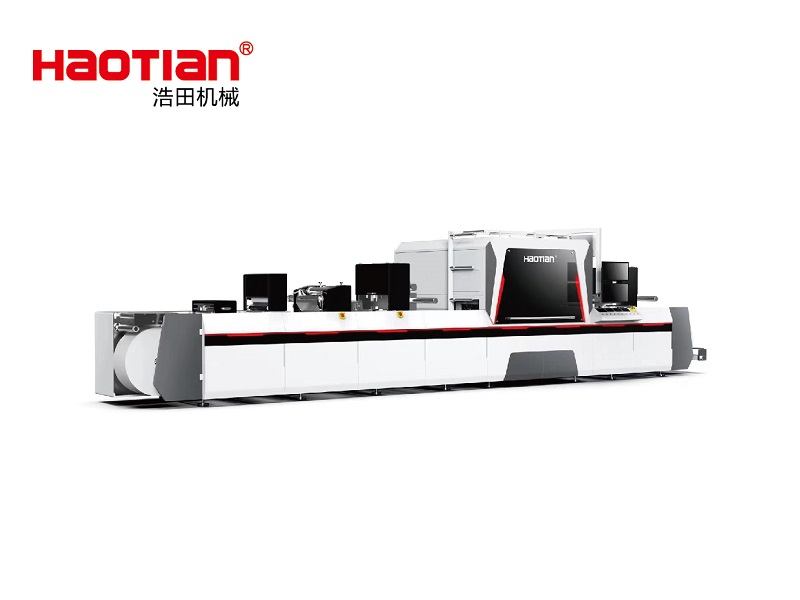

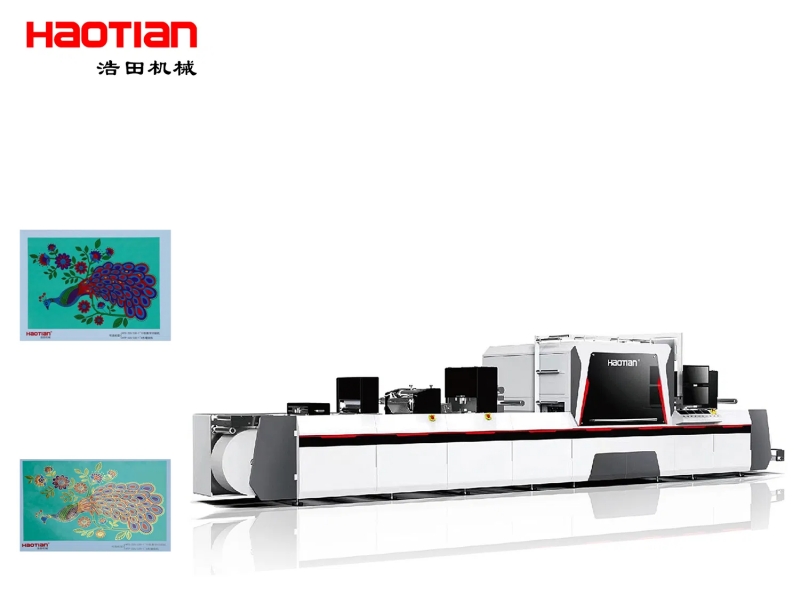

The HGP-220-7C features a multi-functional combination system that integrates optional hot stamping, foiling, and flexographic modules directly within the printing line. This unique one-pass configuration eliminates the need for multiple reprints across different machines, significantly reducing production time and costs. By combining processes into a single streamlined workflow, the system enhances operational efficiency while delivering premium decorative effects for high-value labels.

In addition, the machine supports a multi-spot color module capable of reproducing over 95% of Pantone shades. This broad color gamut allows brands to achieve precise corporate colors and specialized finishes without relying on additional processes. By expanding design flexibility and reducing ink usage, the HGP-220-7C not only ensures vibrant, accurate output but also offers a sustainable and cost-efficient solution for diverse label applications.

PEFORMANCE AND FEATURES

1. Multi-Material Compatibility

Supports a variety of materials, including paper, PVC, PET, PE, BOPP, and gold and silver foil, eliminating the need for pre-coating and reducing process steps and costs.

2. High-Quality Full-Color Printing

Using the CMYK+W color palette, it enables full-color direct printing on both transparent and opaque materials, eliminating the need for platemaking.

3. Powerful Variable Data Printing

Supports variable data such as barcodes, QR codes, serial numbers, and dot matrix codes, enabling "one item, one code" and meeting anti-counterfeiting and traceability requirements.

4. Efficient Production and Low Cost

Simple operating software allows for fast order changeover; consumables and printhead costs are similar to those of traditional printing, significantly reducing production costs.

5. Patented Automatic Printhead Maintenance

The unique e-clean fully automatic printhead cleaning and maintenance system extends printhead life, reducing ink waste and manual labor.

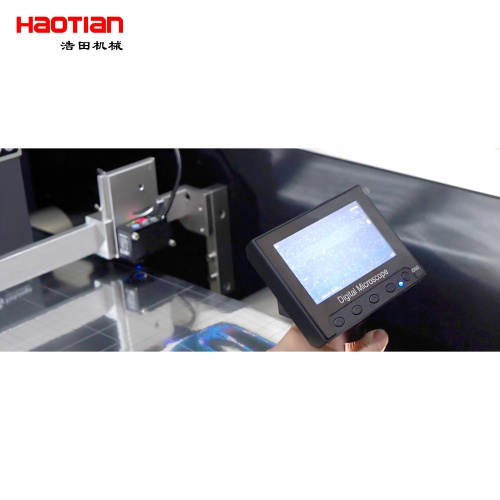

6. Stable and Precise Printing Control

Equipped with a circulating ink supply system, dual servo tension control, closed-loop rewind and unwind control, and electrostatic/dust removal devices, it ensures smooth paper feed and precise registration.

7. Environmentally Friendly and Superior Quality

This product utilizes environmentally friendly UV ink (VOC-free) and features a water cooling system to prevent deformation of the film substrate. Combined with professional color calibration tools, it ensures high stability and high-quality output.

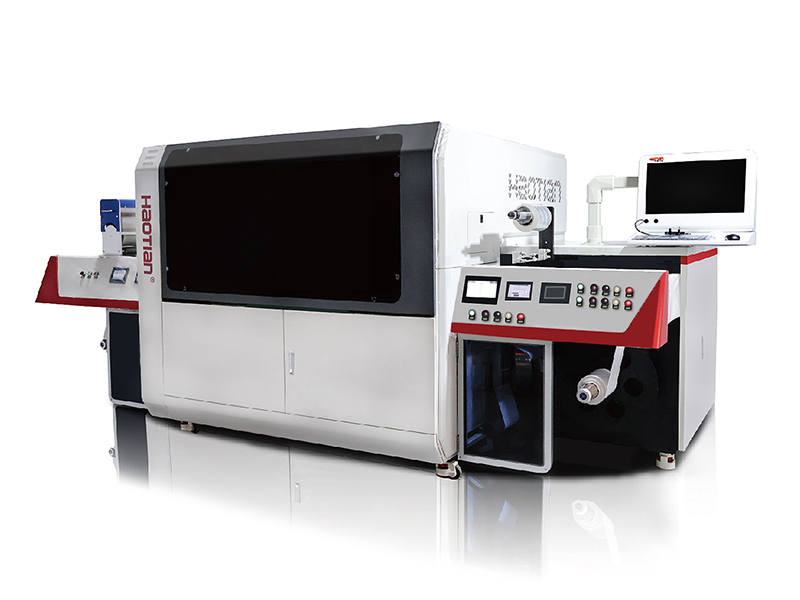

Globally Unique System

Our independently developed integrated printhead drive system enables simultaneous control of printheads from multiple brands using a single system. This allows for simple operation, leveraging the strengths of each printhead to enhance and guarantee printing results.

Multi-functional Combination

Optional front and rear flexographic plates are available. 4-9 color inkjet printing is available in the middle, and hot stamping and foiling can be added for enhanced efficiency, eliminating the need for multiple reprints. Single-step printing reduces costs.

Multi-Spot Color Module

Supports over 95% of Pantone colors, offering a wider color gamut, expanding the printing range, reducing process steps, and lowering ink costs.

Specification

| Model NO. |

HGP-220/330-4~9C |

| Applicable Materials |

Semigloss, Film, Universal Label Roll PAC |

| Actual Printing Width |

216mm/324mm(Maximum) |

| Specification |

Approximately 4.2 tons |

| Origin |

Baiyun District, Guangzhou City, Guangdong Provinc |

| Production Capacity |

50m/Min |

| Printing Color |

Nine Colors |

| Paper Feed Width |

250mm/350mm(Maximum) |

| Transport Package |

Packing in Non-Air Wooden Case |

| Trademark |

HAOTIAN |

| HS Code |

8443322190 |

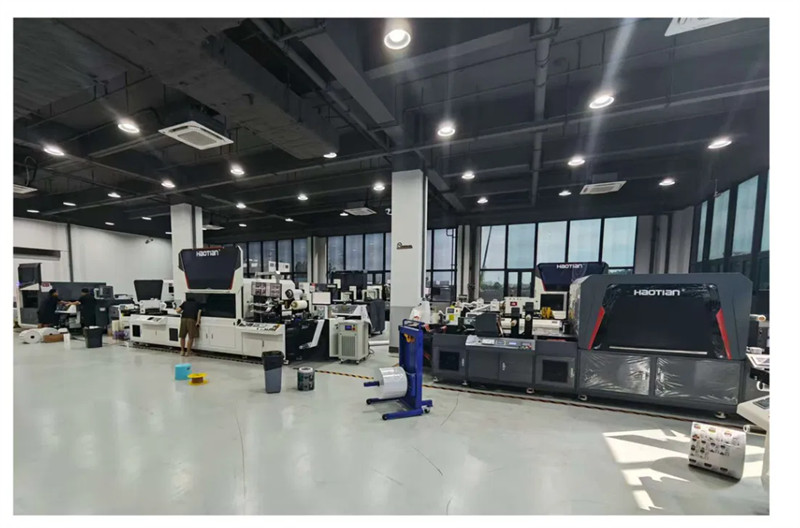

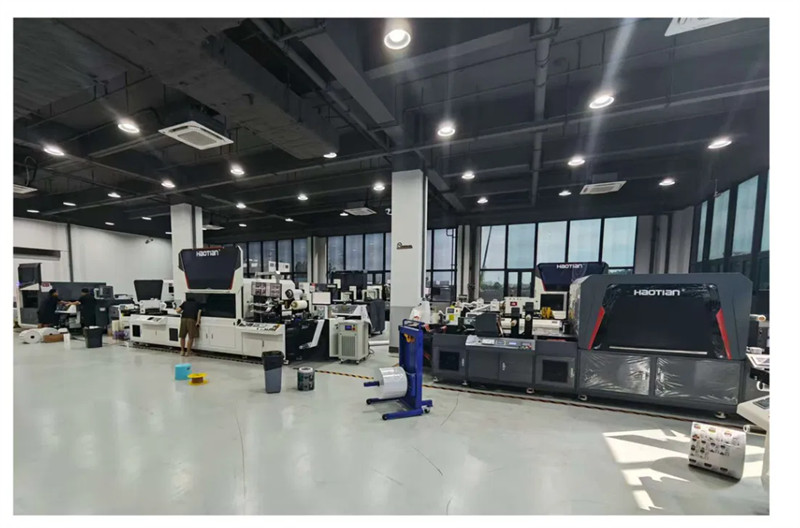

Factory & Packaging

Our Certificate

en

en

Tel :

Tel :  E-mail :

E-mail :

Network Supported

Network Supported