In today’s fast-paced manufacturing and creative industries, UV digital printing has revolutionized the way businesses produce graphics, logos, and customized designs. Unlike traditional printing techniques that rely on heat or solvent evaporation, UV printing uses ultraviolet (UV) light to instantly cure ink on a wide range of materials. This not only makes the process faster but also ensures higher durability and sharper results.

Whether you are a packaging manufacturer, a sign-making company, or a business exploring product customization, understanding how UV digital printing works can help you decide whether this technology is the right investment.

The Technology Behind UV Digital Printing

At its core, UV digital printing combines specialized inks with ultraviolet curing technology. Here’s a breakdown of how the process works:

-

Digital Image Preparation

The process begins with a digital file, usually designed using software like Adobe Illustrator or CorelDRAW. The printer translates this file into precise printing instructions.

-

Ink Application

Instead of traditional solvent-based inks, UV printers use specially formulated UV-curable inks. These inks stay in liquid form until they are exposed to UV light.

-

UV Curing with LED Lamps

As the ink is applied, powerful UV LED lamps follow immediately, exposing the ink to ultraviolet light. This causes a chemical reaction known as photopolymerization, which transforms the liquid ink into a solid instantly.

-

Final Output

The result is a sharp, vibrant, and durable print that adheres firmly to the material surface without requiring drying time. This is why a UV flatbed digital printer can produce dozens or even hundreds of high-quality prints in just a short time.

Advantages of UV Printing Compared to Traditional Methods

UV digital printing offers numerous benefits over conventional technologies such as screen printing, offset printing, or solvent-based methods:

-

Instant Drying – Since the ink is cured immediately, there is no waiting time, and production speed increases dramatically.

-

Wide Material Compatibility – UV printing works on glass, wood, acrylic, plastic, leather, ceramics, and even metal surfaces.

-

High Durability – Prints are resistant to scratches, fading, and water, making them ideal for outdoor signage or long-term use.

-

Eco-Friendly – UV-curable inks release fewer volatile organic compounds (VOCs), making the process more environmentally sustainable.

-

Cost Efficiency for Small Batches – Unlike traditional printing that requires plates or screens, UV printing can handle small-volume or personalized orders without additional setup costs.

This explains why more companies are switching to an industrial UV digital printing machine to expand their production capacity and meet growing customer demands.

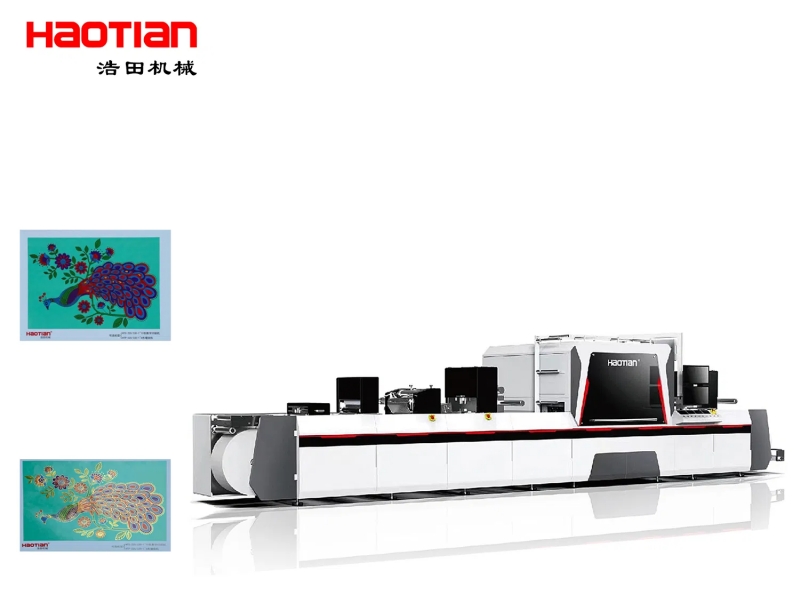

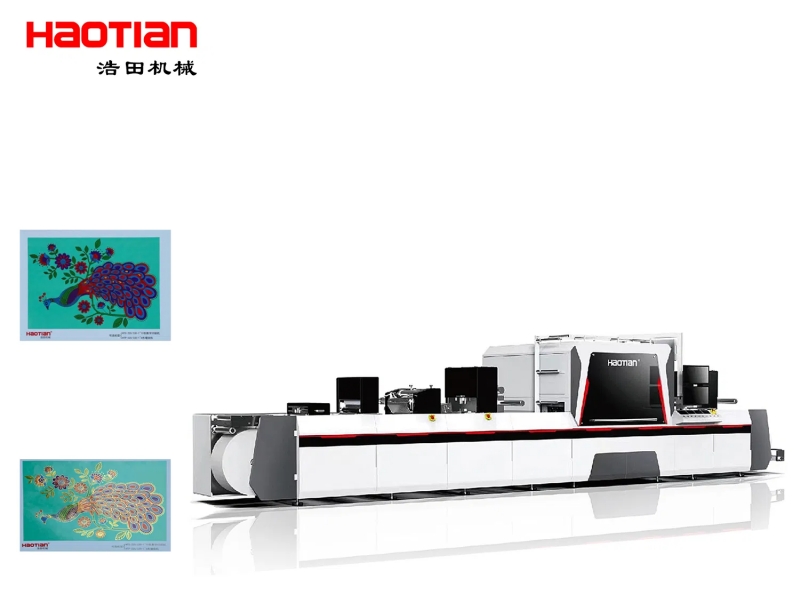

Types of UV Digital Printers

Not all UV printers are the same. Depending on the application, businesses may choose from different models:

1. Flatbed UV Printers

A flatbed printer has a flat surface where materials are placed for printing. These are especially popular because they can print directly onto rigid substrates like glass, wood, or metal. Many small and medium enterprises use a UV flatbed digital printer for promotional products and customized gifts.

2. Roll-to-Roll UV Printers

These printers handle flexible materials such as vinyl, banners, or wallpapers. They are widely used in advertising, interior décor, and large-format printing.

3. Hybrid UV Printers

Hybrid printers combine flatbed and roll-to-roll functions, making them versatile for companies that need to handle both rigid and flexible materials.

By choosing the right printer type, businesses can maximize their return on investment and improve overall efficiency.

Applications of UV Digital Printing

The versatility of UV printing makes it ideal for numerous industries. Some common applications include:

-

Packaging – Printing high-quality labels and decorative finishes on cardboard, plastic, and glass packaging.

-

Advertising & Signage – Creating large outdoor banners, indoor signs, and retail displays that require long-lasting, vibrant colors.

-

Promotional Items – Customizing pens, phone cases, USB drives, and corporate gifts.

-

Home Décor – Printing on furniture panels, ceramics, and wall art.

-

Electronics & Industrial Products – Marking logos or instructions directly onto machine parts, metal plates, or glass panels.

Because of this adaptability, UV printing has become one of the fastest-growing printing technologies globally.

Quality and Resolution in UV Printing

One of the most attractive features of UV technology is its ability to achieve exceptional resolution and detail. With precision inkjet heads and controlled curing, printers can deliver images with resolutions up to 2400 DPI.

This makes it possible to reproduce fine text, photographic images, and intricate patterns with outstanding clarity. Businesses that need professional-grade results often invest in high resolution UV printing equipment to meet customer expectations.

Maintenance and Best Practices

Although UV printers are efficient and durable, proper maintenance is essential to ensure consistent performance:

-

Regular Cleaning – Printheads must be cleaned to avoid clogging.

-

Proper Ventilation – UV curing requires a well-ventilated environment for safety.

-

Ink Storage – UV inks should be stored properly to maintain their chemical stability.

-

Software Updates – Keeping RIP (Raster Image Processor) software updated ensures smooth operation and color accuracy.

By following these practices, companies can extend the lifespan of their printers and maintain high-quality output.

Future Trends in UV Digital Printing

The UV printing industry continues to evolve with new innovations:

-

Faster Production Speeds – Improved printhead technology and stronger UV LEDs are making production faster.

-

Expanded Material Compatibility – New ink formulations are allowing printing on textiles and more flexible substrates.

-

3D and Texture Printing – Advanced UV systems can create embossed effects and raised textures, adding value to products.

-

Sustainability Improvements – As businesses prioritize eco-friendly solutions, more energy-efficient UV curing systems are being developed.

These trends will further strengthen the role of UV printing across global markets.

UV digital printing represents a major step forward in modern printing technology. By using ultraviolet light to instantly cure inks, it delivers sharp images, fast production, and outstanding durability across a wide variety of materials. From packaging and signage to customized products and industrial applications, this method gives businesses greater flexibility and creative possibilities.

As the technology continues to evolve, we can expect even faster machines, improved sustainability, and more applications in everyday life. For companies seeking high-quality printing solutions, UV digital printing is not just a trend—it is the future of the industry.

en

en

Tel :

Tel :  E-mail :

E-mail :

Network Supported

Network Supported